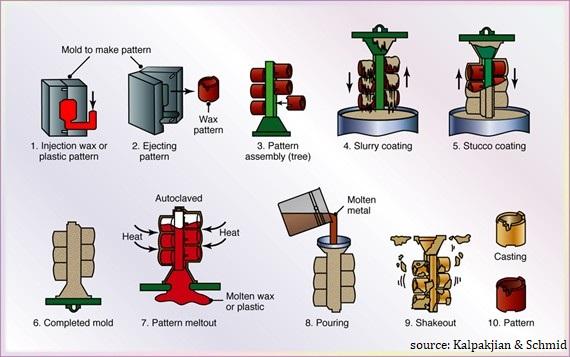

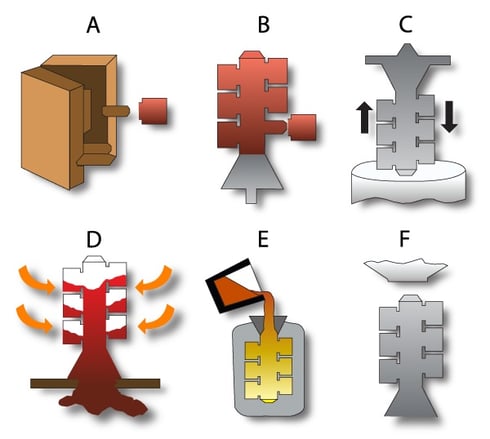

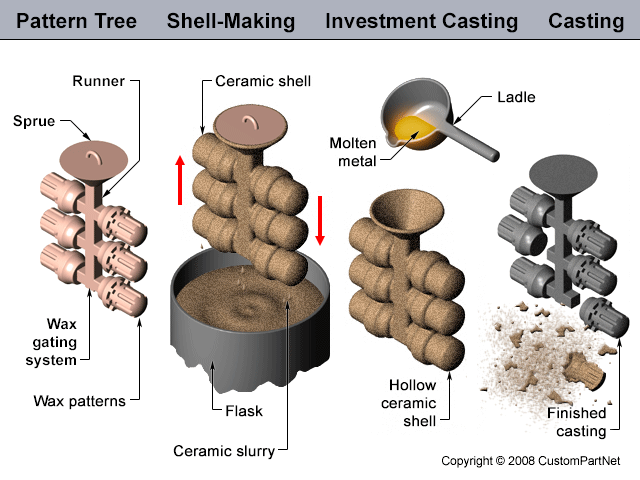

In this type of casting mould is prepared around an expandable pattern and a single gating system is used to make a large number of casting. Furthermore the investment casting process is relatively simple which allows for high production rates and consistent dimensional accuracy.

Precision investment casting process applications advantages and limitations mecholic.

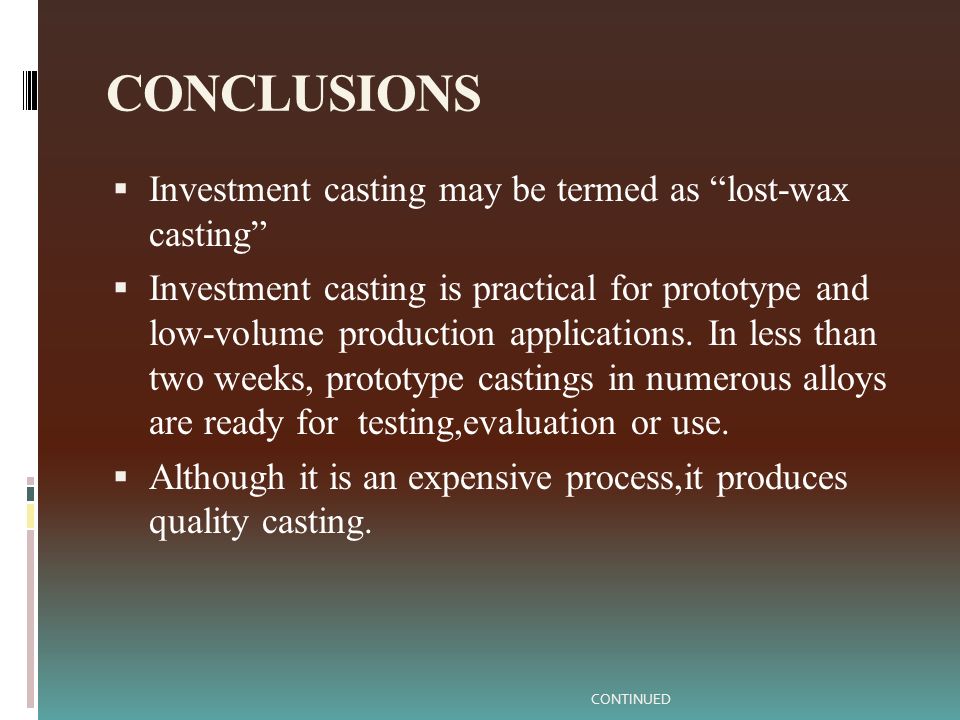

Investment casting process applications. But still investment casting is largely relied on for complicated designs that cannot be casted using any other method. Investment casting which is also known as lost wax casting. It uses a replication of a wax patterns to create parts.

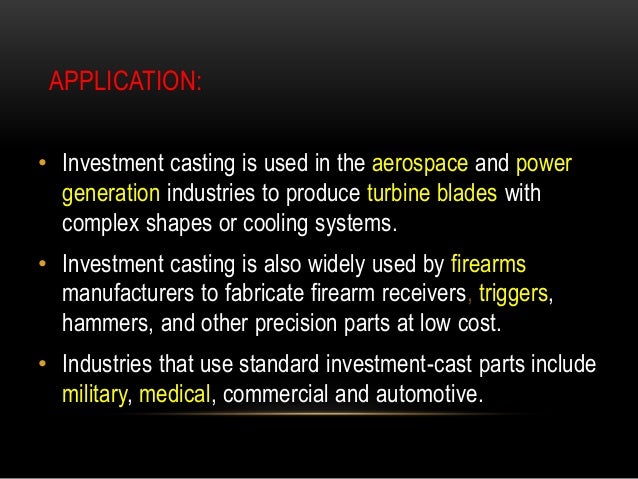

Investment casting finds widespread application in spacecraft jet engines etc. It is a method of precision casting process to manufacture small complicated parts using almost all alloy. This process is more expensive than sand casting in terms of the casting techniques but the equipment are relatively cheaper.

The pattern used to make mold is get destroyed or it completely lost its shape during. Investment casting provides the ultimate design flexibility for highly complex parts made from a large choice of alloys. Although 3d printing does not solve all the issues of investment casting it makes it more feasible for manufacturing companies that are geared towards automation or want to achieve better consistency and.

Investment casting is an old and well established manufacturing process but its integration with 3d printing just breathes new life into it.

Investment Casting An Overview Sciencedirect Topics

Investment Casting An Overview Sciencedirect Topics

What Is Investment Casting Advantage Disadvantages

What Is Investment Casting Advantage Disadvantages

Investment Castings What Are Investment Castings Used For

Investment Castings What Are Investment Castings Used For

Investment Casting Process Precision With Dean Group

Investment Casting Process Precision With Dean Group

Precision Investment Casting Process Applications Advantages And Limitations Mecholic

Precision Investment Casting Process Applications Advantages And Limitations Mecholic

What Is Investment Casting And How Does It Work

What Is Investment Casting And How Does It Work

Gating System Casting Processes Ppt Video Online Download

Gating System Casting Processes Ppt Video Online Download

Investment Castings Ppt Video Online Download

Investment Castings Ppt Video Online Download

0 comments:

Post a Comment